I used to have an '88 Blazer and never had any rear glass issues, so I'm surprised with the number of issues first gen 4Runners have with their rear glass. At the end of the day, it's all pretty straightforward - once you know everything about them! :)

Since the truck has been relatively unmolested, I assumed something had gone bad. Err, no. In the process of diagnosing this, I started with the relay since it had had issues before, and also replaced the tailgate switch. The troubleshooting process for those two issues is linked at the end of this article.

PROBLEM description

The switched Blue/Black-stripe thin wire to the tailgate has power at the relay, but not at the tailgate switch, checked where it exits the body and enters the tailgate, and again at the tailgate switch. If I ground it at the relay, the window goes up (trips the relay, and ta-da!).

Things I learnededed [sic]

Anywhere I say "ground ... wire X" below, I mean I used a test lamp and it kicked the relay.

Example: I "grounded" the blue/black thin wire (tailgate switch wire) at the relay, causing the rear window to go down, ignoring interlocks - I was able to extend the window with the gate open. I only extended it a couple inches since breaking it is not high on my list of to-do's. Using the switches, interlocks work as intended.

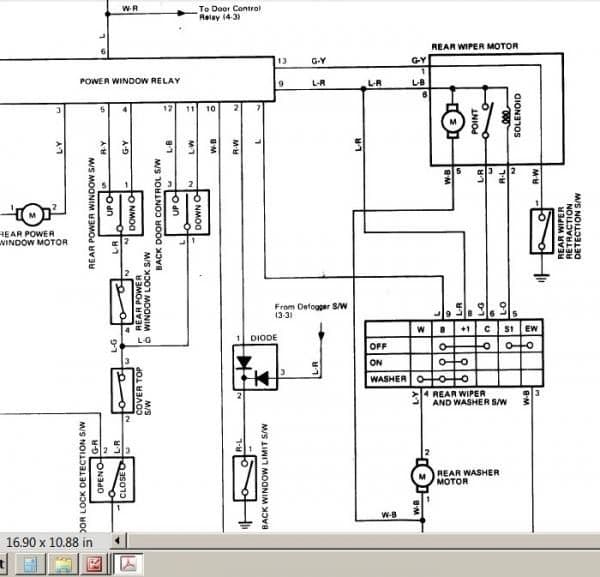

Some wire color notes for my '87 SR5, colors at the master window relay, and before the center-console interior switch pigtail (chassis-side).

Any of the thin wires below grounded with a test light will actuate the rear window.

Rear window down:

- Blue/White stripe : wire to tailgate, 12v at the relay

-- Thin one actuates relay, goes from relay to tailgate switch. 12v at the relay, 12v at the tailgate switch.

-- Thick one powers motor only, 12v at relay when relay is tripped

- Green/Yellow : center console switch. 12v at the relay at all times

Rear window up:

- Blue/Black stripe : wires to tailgate.

-- Thin one actuates relay/ goes from relay to tailgate switch. 12v at the relay. I suspect it's supposed to have 12v at the tailgate switch.

-- Thick one powers motor. 12v at all times

- Red/Yellow : center console switch. 12v at the relay at all times

Let's get on with it, then!

Here's the wiring diagram, colors match (L-B is Blue/Black)

Turns out there's a connector inside the jack compartment - which I'd completely forgotten existed. I'd thought I'd have to pull the whole side panel to get at the harness. Boy, was that a nice surprise!

Once inside the jack compartment, I found someone's method of testing wires involved slicing the insulation off. Or more. Here's the harness on the truck side, where they were looking for the wires to the tail-light. You know, the ones that exit the harness just below that and go to the tail light...

Following that harness straight down is a connector to the tailgate harness. Power on both sides for our little Blue/Black wire. Aha... Suddenly the fat part of the harness under the truck made sense.

I was able to pull the harness out of the body and work on the broken parts above the tailgate (See the hole where the "aftermarket" trailer wiring exits - there's a rubber plug for that hole - I'd pulled it out while working on this, and the connector is dangling below the truck. Don't leave it like that, the quarter will fill with rocks and mud).

In the bright SoCal sunlight, with the wires cleaned up, this was the extent of the damage. Look at those slices in the insulation (and the above pic shows the green wire completely cut through). I'm holding the Blue/Black wire - corrosion had damaged the 2 remaining wire strands.

After some splicing. I needed to use multiple butt connectors or completely replace the wires.

I used liquid electrical "tape" on the wires which retained their integrity but had their insulation sliced open.

After this pic, I also used the liquid tape to seal the butt connectors as this part of the loom hangs under the truck and gets a lot of mud thrown at it and will be under water from time to time using past experience to guide me.

My son, Andrew, was helping me as he always does. He found this floating around in the tailgate. Good thing, I can see it cracking the glass during some high speed offroading. I've been in there 3 times and never saw it.

A bit later, a friend of his came over, so they played some version of HORSE. That Aluminess bumper sure is handy. And only like 60#, ridiculously light for a winch bumper. Let them know I sent you when you call over there, it's worth $50 off to you. They used my 4Runner for the firstgen Toyota template. Great shop, great guys. :)

A bit later, a friend of his came over, so they played some version of HORSE. That Aluminess bumper sure is handy. And only like 60#, ridiculously light for a winch bumper. Let them know I sent you when you call over there, it's worth $50 off to you. They used my 4Runner for the firstgen Toyota template. Great shop, great guys. :)

It feels really good to have the window working from the tailgate switch.

Here's the YotaTech thread solving this, there is more detail and more pics.